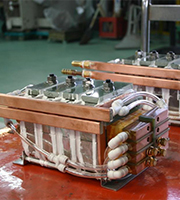

Our coils created using our own original knowhow makes high-performance high-frequency induction heating a reality.

Only coils that match the properties of the heated material are able to bring out the full performance capabilities of the units that construct the device.

Because of this, it is safe to say that the knowhow regarding the design of coils is the core technology in the production of high-frequency induction heating devices.

Hagoromo Electric Corporation has long been focusing its efforts to improve the production technology of coils and other related products as a specialist manufacturer of this field.

Induction heating coils for forging and other related products

Induction heating coils for iron and steelmaking and other related products

Others

Service life extension via various processes

We provide high-quality low-cost coils.

The coil and heated material do not come in direct contact within the high-frequency induction heating devices. However, coils meet the end of their service life quickly unless durability measures with factory environments taken into consideration are applied. And so we at Hagoromo Electric Corporation have prepared various processing techniques in order to extend the years of our product's service life to the greatest. Our variety of durability measures range from insulation processing by taping, varnish, powder coating and vacuum impregnation to heat protection treatment of sleeves and plating as well as the incorporation of special fire-resistant materials. We provide a design that is the most suitable to the factory environment and operating conditions of the facilities of our clients to achieve service life prolongation of our coils.

Insulation process

Taping

Electrostatic powder coating

Insulating Varnish

Heat protection treatment

Fire-resistant cement

Fire-resistant sleeve

Fire-resistant plate

Our services are also available to products from other companies.

We offer coil repair services on a countrywide scale.

Our coil repair services are available to all coils, including products of other companies. Another strength of Hagoromo Electric Corporation is the ability to not only provide repairs but also offer fundamental solutions to problems. Please feel free to contact us whenever you face any coil-related problems. We would be happy to diagnose and offer a solution for your facility, wherever it may be in the country. As well as suggest the most power-efficient coil that is suitable for your factory environment.

It is our hope that all companies interested in a higher degree of efficiency employ our services for coil diagnostics at least once. Our technology and knowhow cultivated in Japan have also received high acclaim from overseas clients. In one case, an overseas company saw a 10 to 30% increase in performance efficiency due to the analysis and redesigning of their coils being used.

Delivery record

Induction heating equipment manufacturers

Manufacturers of high-efficiency induction heating equipment for forging

Major shipbuilding company listed with the first section of the Tokyo Stock Exchange

International induction melting/heating equipment manufacturers

Induction melting furnace equipment manufacturers

Related to forging

Major automobile parts manufacturers

Major automobile parts manufacturers listed with the first section of the Tokyo Stock Exchange and more

Related to iron and steel manufacture

Many major iron and steel manufacturers listed with the first section of the Tokyo Stock Exchange

Order

We generally follow the below order until final delivery, starting with the initial inquiry which will be followed by a pre-hearing survey. The below order is for reference and we will respond flexibly depending on the situation and circumstances.

On-site inspection

As a general rule, we conduct all diagnostics and inspects on-site. We will discuss your requests and current issues in detail.

Report on the projected effect

We will come up with workable suggestions after taking the on-site inspection results into consideration. We will prepare and share a simulation of the projected effect and results with you.

Production

With your approval, we will begin production. It is possible to visit the production site if you would like. Please feel free to visit our facilities.

Operation test review

An operation test will be conducted on the manufactured product. A review of the operation test will be submitted to you followed by the final delivery of the product.Post-delivery support will be available if required.

Increase in efficiency

We make increased efficiency a reality by our products that meet all expectations. Our highly durable products aid in the reduction of running costs which our clients find extremely satisfying.